ABOUT US

Company Introduction

Akshar Rice & Pulse Mills Pvt. Ltd. is a professionally managed organization which specializes in providing comprehensive range of Basmati/Non-Basmati Rice, Wheat & Pulses; all of which is processed at our own production facility in Dist. Kheda, Gujarat.

Our company has been established in 2013, with our new market brand name Akshar (previously known as Dipak). The milling unit, consisting of state-of-art machineries, newly installed as per the latest advance technological trends with faster processing, produces high quality sortex rice, wheat & pulses.

Products milled at our plant have consistent quality, best known for its taste, nutritional value and texture. We offer a range of finely graded and fully sorted (free of discolored grains) products in various packet sizes ranging from 10kg to 50kg at competitive prices. We market our products mainly through wholesalers, distributors and mass retailers in domestic and international markets. We also provide other commodities such as edible oil, sugar and other foodstuff.

Due to our high quality control and timely services we have secured clients such as BAPS Swaminarayan Sanstha (All Gujarat), Alembic Ltd (Baroda) etc. to name a few. Kindly send all inquiries to info@aksharmills.com. We shall be awaiting your enquires and hopeful to have you as our esteemed customers.

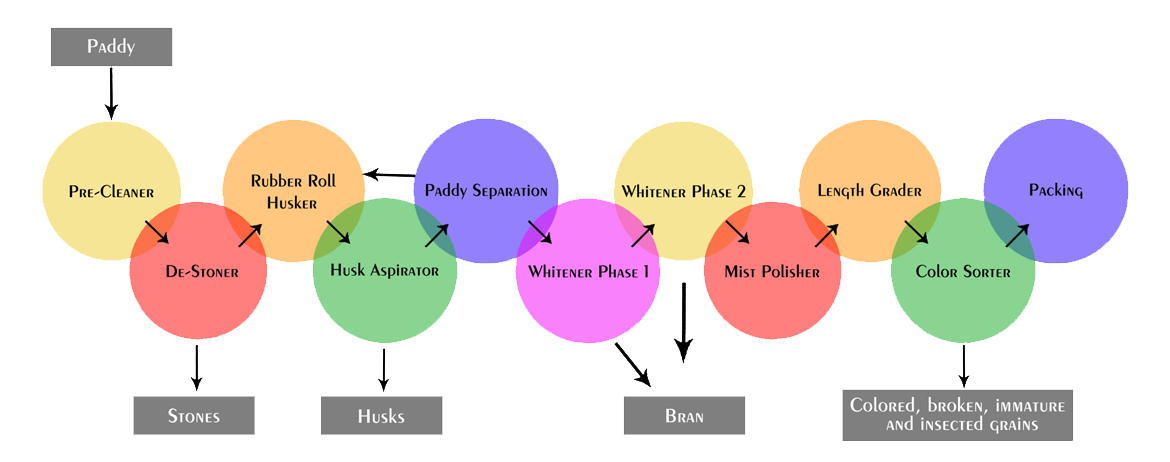

Rice Milling Process

Paddy in its raw form cannot be consumed by human beings. It needs to be suitably processed for obtaining rice. Rice milling is the process which helps in removal of hulls and barns from paddy grains to produce polished rice. Rice forms the basic primary processed product obtained from paddy and this is further processed for obtaining various secondary and tertiary products.

The basic rice milling processes consist of:

-

Paddy cleaner is the most essential equipment in a rice mill, as it separates all the impurities like dust, straw, sand, clay and heavy particles of even an uneven sizes from paddy. The advantages with the paddy cleaner are that increases the life of rubber rollers and the percentage of oil in bran.

-

Separating small stones from paddy.

-

This dehusker machine is used for dehusking of paddy and removing of husk. The machine is based on centrifugal principle.

-

Separating the husk from brown rice / unhusked paddy.

-

Separating the unhusked paddy from brown rice.

-

Removing all or part of the bran layer and germ from brown rice. The whitener is used for whitening (i.e. removal of bran) of brown rice to white rice. Through a smooth flow of rice and the efficient aspiration system inside the machine, the rice is whitened very gently.

-

Improving the appearance of milled rice by removing the remaining bran particles and by polishing the exterior of the milled kernel.

-

Separating small and large brokers from head rice.

-

Removing foreign materials such as colored, broken, immature and insected grains from milled rice

-

the milled rice for transport to the customer